Table Of Content

Table Of Content

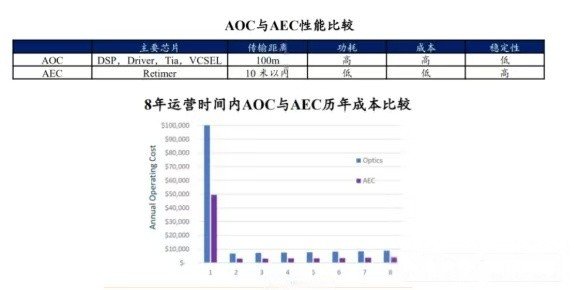

High-speed copper cables can be divided into three major categories: passive copper cables (DAC), active copper cables (ACC), and active electrical cables (AEC). Often referred to as the “second growth curve” for copper cabling, AECs integrate retimer chips at both ends of the cable to amplify and regenerate signals. This solves the signal-attenuation issues that occur during long-distance copper transmission and makes AECs an emerging choice for high-speed interconnects within data centers.

Compared with traditional passive DACs, AECs support longer transmission distances and significantly improve signal integrity. They are expected to be widely deployed on the Ethernet access side in the future, including in AI inference and training architectures.

According to Light Counting, as domestic manufacturers continue to make breakthroughs in materials, chips, and system integration, the global AEC market is projected to grow at a 45% CAGR from 2024 to 2028. By 2028, the combined market for AOC, DAC, and AEC is expected to reach USD 2.8 billion—reshaping the data-center connectivity ecosystem.

Introduction to AEC Copper Cables

AEC (Active Electrical Cable) is a type of copper cable constructed from small-gauge copper wires and equipped with industry-standard connectors at both ends. These connectors integrate low-power, high-performance retimers, gearboxes, and FEC circuitry to ensure signal integrity at 56G and 112G per-lane data rates across lengths from 0.5 to 7 meters.

The internal SerDes devices handle both retiming and rate conversion, making AECs lighter, smaller, and more reliable compared to alternative solutions.

Key Features of AEC

AEC technology offers six core advantages:

1. Low Power Consumption – Lower power draw compared with traditional copper and optical solutions.

2. Lightweight Design – Optimized materials and construction significantly reduce overall weight.

3. Long Lifespan – Enhanced durability makes AEC ideal for long-term deployments.

4. Improved Bend Radius – Greater flexibility and smaller bend radius for high-density routing environments.

5. Speed Shifting & Retiming – Supports signal retiming and data-rate conversion to ensure high-quality transmission.

6. Standards Compliance – Fully compliant with industry specifications, enabling seamless integration into existing infrastructure.

How AEC Differs from DAC

Unlike the DAC supply chain—where connectors and brand manufacturers play the central role—the core of the AEC supply chain lies in retimer chips and brand integrators. Retimer self-sufficiency is a critical factor determining production costs, meaning retimer suppliers are likely to become the dominant forces in the future AEC ecosystem.

In DACs, the dielectric layer in the copper cable must be enlarged to reduce electromagnetic interference between twisted pairs, especially at higher speeds. Without retimers, DACs require thicker dielectric layers, making the cable bulkier.

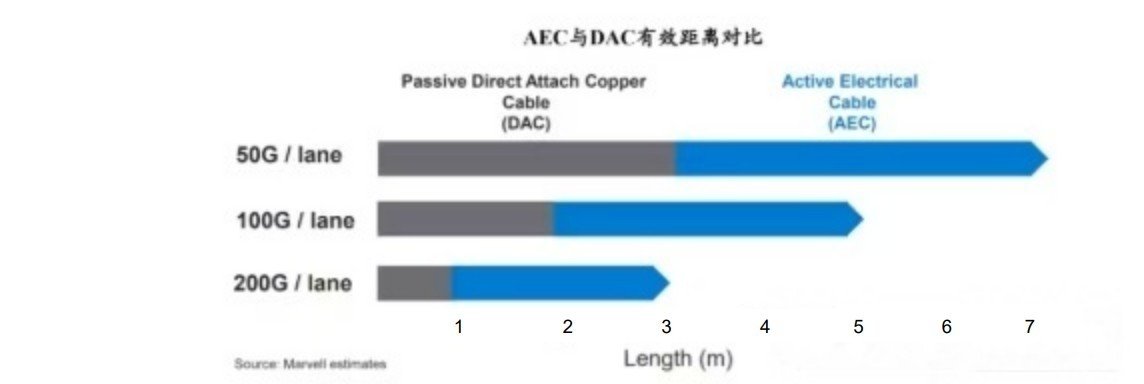

Below is a comparison between DAC copper links and AEC solutions:

1. Working Principle amp; Structure

DAC Copper Link: A passive copper-to-copper connection with no signal-processing chips—just copper cable and connectors.

AEC: Integrates CDR/retimer chips at both ends to re-clock and re-drive electrical signals, improving transmission quality.

2. Transmission Distance

DAC (Under 3 meters): Due to inherent copper-signal attenuation, DACs support very short reach—generally within 3 meters, and only around 1 meter at 224G.

AEC (7–10 meters): AECs compensate for copper loss more effectively and block jitter propagation, supporting 7+ meters of reach.

3. Signal Quality

DAC: Prone to attenuation and distortion at higher speeds or longer distances, which increases BER and compromises data integrity.

AEC: Retimers ensure signal recovery and re-equalization, improving signal quality, reducing BER, and ensuring reliable transmission.

4. Cost

DAC: Lower cost and suitable for budget-sensitive, short-reach applications.

AEC: Higher cost due to retimer integration. For example, an 800G AEC can cost around RMB 1,300 per unit.

5. Application Scenarios

DAC Copper Link: Best for short-reach, cost-sensitive environments such as:

intra-server board-to-board connections

GPU-to-GPU or GPU-to-switch short links

AEC: Ideal for medium-reach, high-performance scenarios such as:

rack-to-rack interconnects

CPU server to GPU-server links

server to ToR switch connections

Partial replacement for short-range optical modules

mo

For More Audio Visual connectivity solution, Pls. visit www.starfirecableshubs.com