Table Of Content

Table Of Content

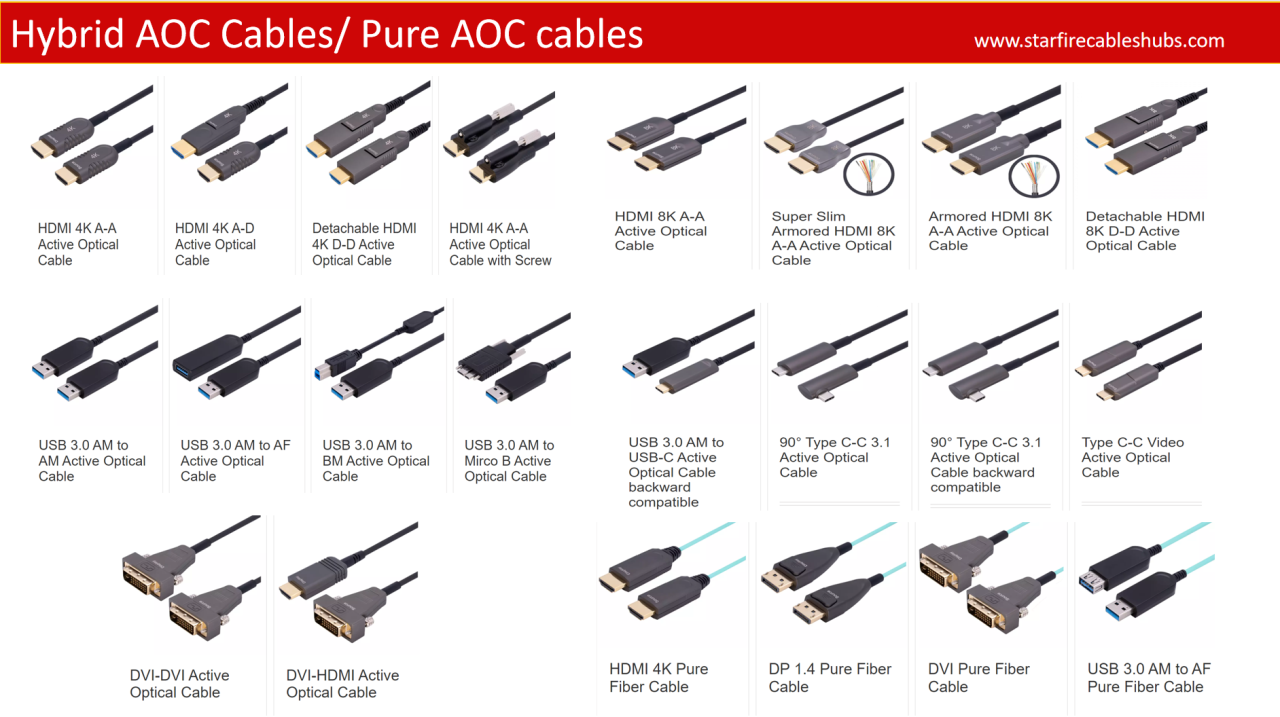

In the competitive world of audiovisual connectivity solutions, not all Active Optical Cables (AOC) are created equal. STAR FIRE TECH, an industry leader established in 2006, prides itself on delivering top-tier AOC products that surpass the competition in quality, durability, and performance. This article highlights the significant differences between STAR FIRE TECH’s premium AOC cables and those offered by other manufacturers.

Superior Raw Materials

PD Chipset on PCB:

- STAR FIRE TECH: Uses Germany’s Silicon-Line chipsets, known for their high-quality and reliability. Silicon-Line is a strategic partner and a key player in formulating HDMI ATC testing standards.

- Other Manufacturers: Typically use local brands, which may not offer the same level of performance and reliability.

- VCSEL on PCB:

- STAR FIRE TECH: Incorporates imported brands like Philips and II-VI, which are recognized for their stability in data centers.

- Other Manufacturers: Often use local brands such as Sinosemic and Tyntek, which may lead to issues like blinking, black screens, and snowflakes after a few months of use, particularly at high resolutions like 4K@60Hz.

- Fiber:

- STAR FIRE TECH: Utilizes OM3 fiber, which provides greater stability and bandwidth, ensuring smooth 18Gbps transmission without delays or errors.

- Other Manufacturers: Use OM1 or OM2 fiber, which are prone to issues like delayed picture and flashing due to smaller bandwidth capabilities.

- Copper Wire:

- STAR FIRE TECH: Uses 99.99% oxygen-free copper (OFC) for power and 19/0.06TC with Kevlar on 30AWG for additional strength.

- Other Manufacturers: Typically use Copper Clad Steel (CSS), which is more fragile and affects the cable’s ductility, especially in installations requiring bending and conduit threading.

- Shielding and Filling:

- STAR FIRE TECH: Features double-layer aluminum foil shielding and DuPont Kevlar filling, enhancing ARC functionality and providing robust tensile strength up to 24kg. Their cables can withstand over 10,000 bending cycles without failure.

- Other Manufacturers: Generally use single-layer aluminum foil and local or no Kevlar, resulting in less effective shielding and lower tensile strength.

Rigorous Testing Procedures

Pre-Testing:

- STAR FIRE TECH: Conducts an 8-hour aging test on modules to ensure stability and longevity, filtering out defective units before assembly.

- Other Manufacturers: May not perform such extensive pre-testing, leading to higher failure rates in the field.

Comprehensive In-Testing:

- STAR FIRE TECH: Employs more than 15 testing procedures covering various brand equipment to ensure compatibility and reliability. This includes optical power value tests and extensive functional tests that guarantee the integrity of TMDS signals.

- Other Manufacturers: May conduct fewer and less thorough tests, potentially compromising the final product’s performance and durability.

Conclusion:

STAR FIRE TECH’s commitment to using superior raw materials, such as German-imported Silicon-Line chipsets and OM3 fiber, combined with rigorous testing procedures, ensures their AOC products are among the best in the market. This meticulous approach results in cables that offer unmatched performance, reliability, and longevity, making STAR FIRE TECH a preferred choice for over 50 branded customers.

By choosing STAR FIRE TECH’s premium AOC cables, customers can expect a product that not only meets but exceeds industry standards, providing a stable and high-quality connection for all their audiovisual needs.

For more audio visual connectivity solution, Pls. discover more: www.starfirecableshubs.com