Table Of Content

Table Of Content

In the professional audiovisual (Pro AV) industry, the integrity of signal transmission and the reliability of system components are paramount. Whether it’s for high-speed digital communication, audio-video signals, or data integrity, the materials and construction of cables and connectors play a crucial role. Specific standards and specifications must be met to ensure high performance and longevity. Among these, gold-plated pins, controlled differential impedance, and comprehensive electrical testing are key factors. Let’s explore what these requirements mean, why they’re essential, and how they contribute to the overall reliability of Pro AV systems.

Gold-Plated Pins and Connectors

Gold-plated pins are a common requirement for high-quality connectors, particularly in professional systems that demand long-term reliability. The reason behind this is simple: gold is an excellent conductor of electricity and has a superior resistance to corrosion and oxidation compared to other materials like copper. In environments where connectors experience frequent insertion and removal (mating cycles) or are exposed to harsh conditions such as high humidity, temperature fluctuations, or corrosive environments, gold-plated connectors ensure stable and low-resistance electrical connections over time.

Gold-plated connectors are not only beneficial for longevity but also help maintain signal integrity. The protective gold layer prevents the buildup of oxidation or other impurities on the contact surface, which could otherwise cause signal loss or degradation. In industries where high reliability is crucial — such as aerospace, defense, medical, and industrial applications — using gold-plated connectors ensures that systems continue to function effectively without the risk of failure due to poor connectivity.

Controlled Differential Impedance: 90–110 Ohms

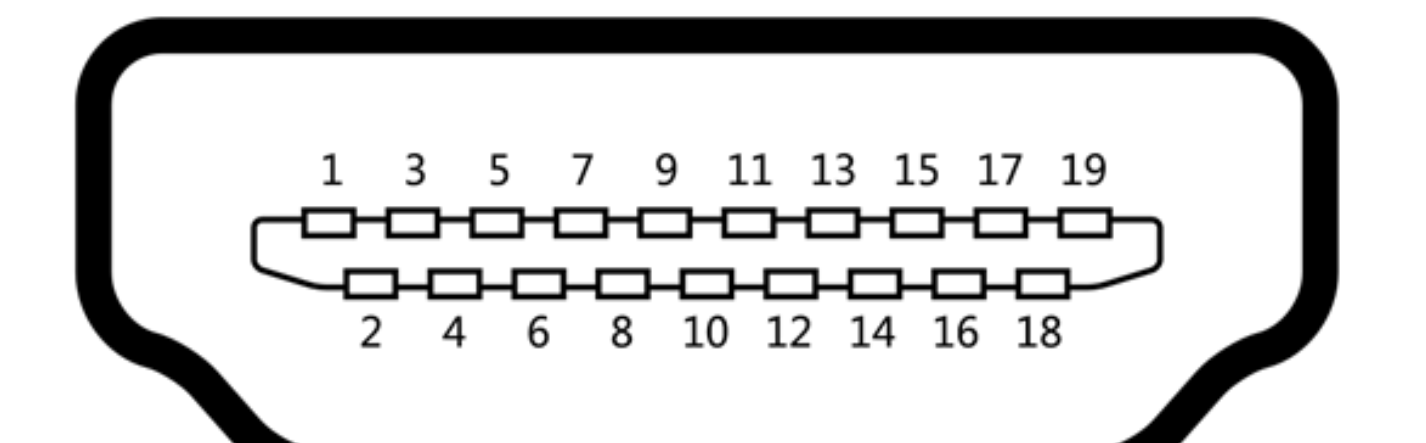

One of the key technical requirements in Pro AV systems is ensuring the signal integrity of high-speed differential pairs, which are commonly used for transmitting data. Differential signaling, as opposed to single-ended signaling, uses two conductors to carry complementary signals. This method significantly reduces the impact of noise and ensures more stable and accurate data transmission.

To achieve this, maintaining a specific differential impedance range (typically between 90–110 ohms) is critical. For high-speed data transmission standards such as PCIe, HDMI, and Ethernet, this impedance control ensures that the signals remain within the desired parameters, preventing signal reflection and loss. Inaccurate impedance matching can lead to signal distortion, reflections, and errors, which can degrade the overall performance of the system.

Differential impedance is a critical factor for high-frequency signal transmission, ensuring that the integrity of the signals is maintained over long distances and across various system components. This is especially important for Pro AV systems where high-definition audio, video, and data need to be transmitted without any compromise in quality.

End-to-End Electrical Testing: Ensuring Quality and Reliability

The requirement for end-to-end electrical testing is essential for ensuring that every connection within the system performs as expected. This testing confirms that the connectors, pins, and cables meet the required specifications for signal transmission and impedance control. By testing all pin pairs electrically, manufacturers can ensure that there are no defects or inconsistencies in the connections that could lead to system failure or poor performance.

In Pro AV systems, where reliability is critical, these tests are crucial to guarantee the proper operation of the system from end to end. Electrical testing not only validates the continuity of the connections but also ensures that the impedance is within the acceptable range, that there are no unwanted reflections, and that there is no signal degradation. This comprehensive quality assurance helps avoid potential issues in live events, broadcasting, or other mission-critical environments.

The Role of TDR Testing in Verifying Signal Integrity

Time-Domain Reflectometry (TDR) testing is one of the most commonly used methods to test cables and connectors for impedance matching and signal integrity. By sending a pulse down the cable and measuring the reflected signals, TDR testing can identify issues such as impedance mismatches, discontinuities, or faults in the cable assembly.

While TDR testing is an excellent tool for verifying electrical performance — ensuring that signal reflections are within acceptable limits and impedance is controlled — it does not necessarily address all the requirements for Pro AV-grade connectors and cables. For example, TDR tests won’t measure the quality of the gold-plated surfaces, their resistance to oxidation, or the mechanical durability of the connectors. Therefore, while a cable or connector passing a TDR test is a good indicator of its electrical performance, it doesn’t guarantee long-term reliability under harsh environmental conditions or after many mating cycles.

High-Performance Cables and Connectors: A Must for Pro AV Systems

In conclusion, the use of high-performance cables and connectors is critical for Pro AV systems that require consistent and reliable signal transmission. Gold-plated pins and connectors ensure durability and stability, especially in environments where high frequency and high-quality signal transmission are essential. Differential impedance control between 90–110 ohms guarantees optimal signal integrity, while end-to-end electrical testing ensures that all connections are functioning as intended.

While passing a TDR test is a positive sign for a cable’s electrical properties, it is just one part of the equation. To truly meet the rigorous demands of Pro AV environments, manufacturers must also consider factors such as gold-plating quality, corrosion resistance, long-term durability, and environmental testing. Only when all of these elements are properly addressed can Pro AV systems achieve the level of performance and reliability needed for critical applications in broadcasting, live events, and other high-stakes industries.

Discover more: www.starfirecableshubs.com

#ProAV #SignalIntegrity #ConnectorStandards #GoldPlating #HighPerformanceCables #ElectricalTesting #ProAVSolutions #ImpedanceControl #BroadcastTechnology #AVIntegration #TechInnovation