Table Of Content

Table Of Content

Choosing the right conductor material for a cable depends on various factors, including the application, electrical performance requirements, and budget constraints. OFC (Oxygen-Free Copper) and BC (Bare Copper) are often preferred over CCS (Copper-Clad Steel) for specific reasons:

- Conductivity: Copper has excellent electrical conductivity, which means it allows the efficient flow of electrical current. Oxygen-Free Copper, in particular, is a high-purity form of copper with lower levels of oxygen and other impurities, resulting in even better conductivity. On the other hand, CCS is a steel core coated with a thin layer of copper. While it is more cost-effective, the steel core has higher resistance than pure copper, leading to lower conductivity.

- Flexibility: Copper is more flexible than steel, making it easier to work with and install in various applications. This flexibility is essential, especially in situations where the cable may need to bend or be routed through tight spaces.

- Corrosion Resistance: Copper is corrosion-resistant, which ensures the longevity and reliability of the cable. Steel, however, is prone to rust and corrosion, which can degrade the cable over time.

- Weight: Copper is lighter than steel, which can be advantageous in applications where weight is a concern. Lighter cables are often preferred for ease of handling and installation.

- Skin Effect: High-frequency signals tend to concentrate near the surface of a conductor, known as the skin effect. Since CCS has a steel core, it may exhibit a more pronounced skin effect than pure copper, potentially affecting the cable’s performance at higher frequencies.

While CCS may be a more economical choice, especially for large-scale installations where cost is a critical factor, it may not be suitable for applications that demand high conductivity, flexibility, and resistance to corrosion. The choice between OFC, BC, and CCS ultimately depends on the specific requirements of the given application and the balance between performance and cost.

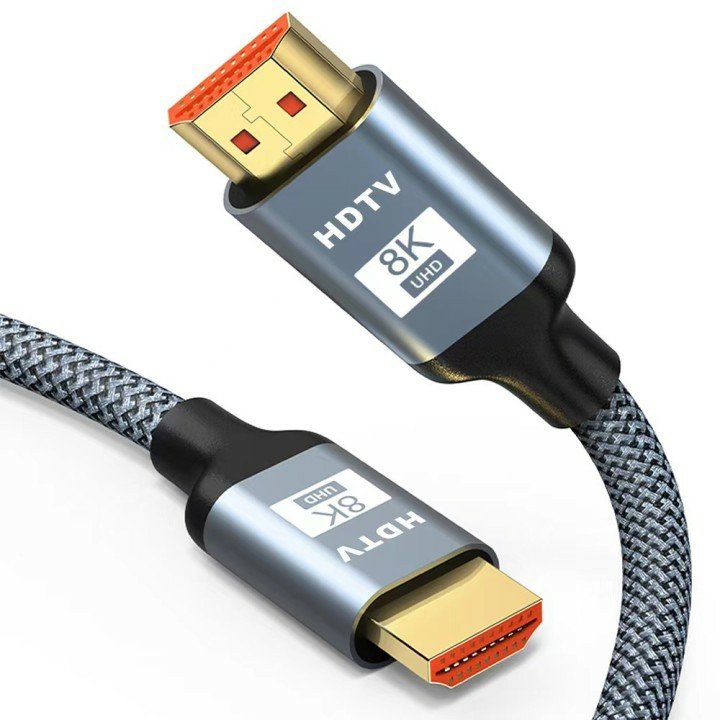

We STAR FIRE, as a professional A/V connectivity| optical fiber communication| Networking communication manufacturing vendor since 2006, are an ISO/ BSCI certified company, IQC/IPQC/OQC/QA covering the whole quality control system, HDMI Adotper, DP VESA Member, USB-IF member, RD with more than 30 people and develop the new products, We got the certification for HDMI 2.1 8K on 2020 and we are the first batch manufacturing vendor passed the HDMI association testing as well as has the USB4, DP2.1 certification on hands. If you would like to find a premium quality cable with certification or would like to find a reliable long-term partner, Pls. kindly contact us at sales@starfiretechcn.com