Table Of Content

Table Of Content

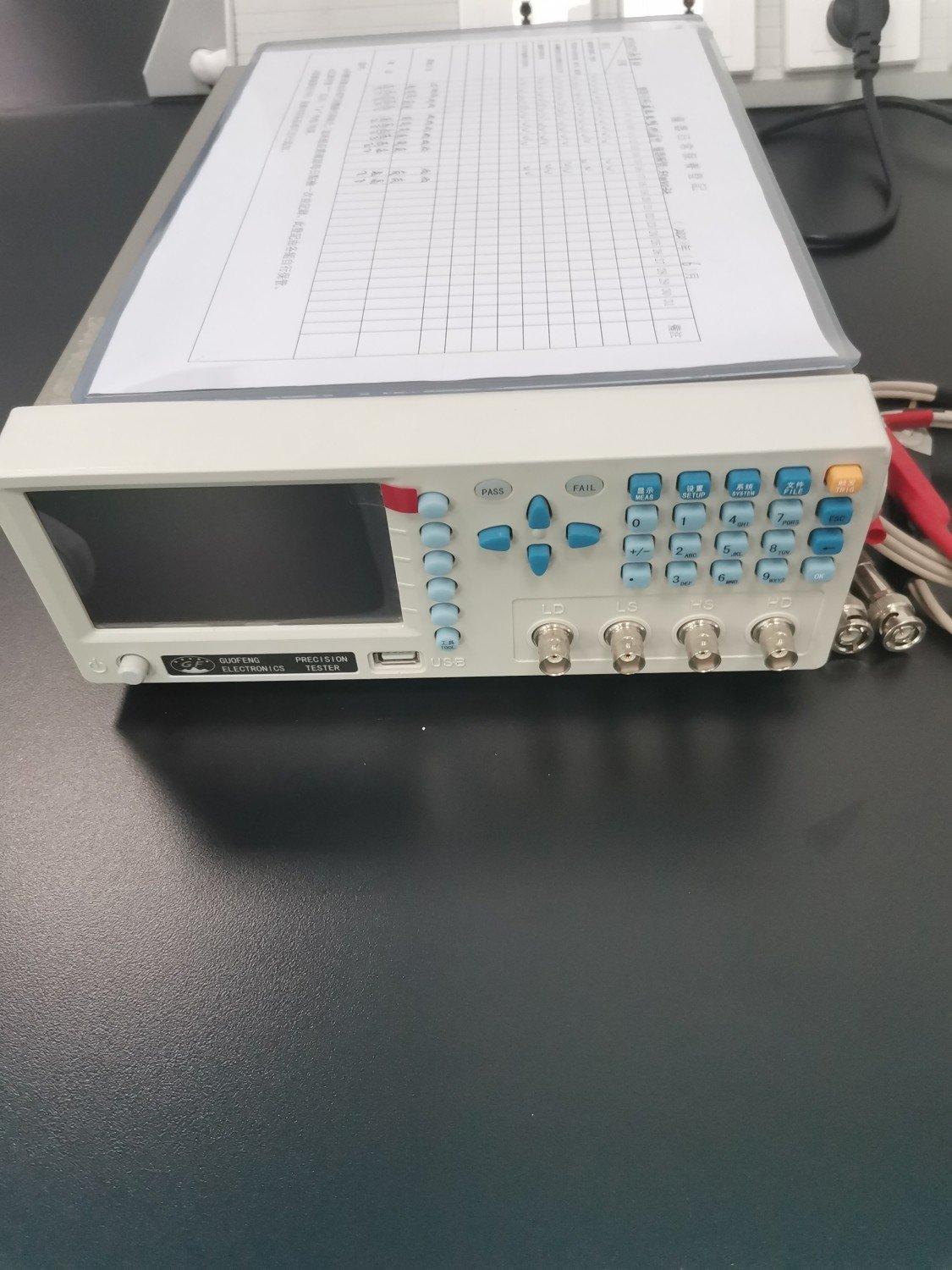

#Time Domain Reflectometry (TDR) testing is a method used to assess the electrical characteristics of cables and other transmission lines. When a cable passes TDR testing with “ultra excellent performance,” it means that the cable demonstrates exceptionally good electrical characteristics based on the measurements taken using TDR.

Several factors can contribute to a cable exhibiting excellent performance in TDR testing:

- Low Signal Attenuation: Attenuation refers to the reduction in signal strength as it travels through the cable. A cable with low signal attenuation allows signals to travel over longer distances without significant degradation.

- Impedance Matching: TDR testing assesses how well the cable’s characteristic impedance matches the system it is part of. A cable with excellent impedance matching minimizes signal reflections and ensures efficient signal transmission.

- Low Crosstalk: Crosstalk occurs when signals on one channel interfere with signals on adjacent channels. Cables with low crosstalk exhibit better isolation between channels, preventing unwanted signal interference.

- Consistent Propagation Delay: Propagation delay is the time it takes for a signal to travel from the transmitter to the receiver. Cables with consistent propagation delay ensure that signals maintain synchronization, which is crucial for high-speed data transmission.

- Quality of Connectors: The connectors at both ends of the cable play a significant role in overall cable performance. High-quality connectors with good contact and shielding contribute to better signal integrity.

- Shielding Effectiveness: TDR testing may assess how well the cable is shielded against external electromagnetic interference (EMI) and radiofrequency interference (RFI). Effective shielding helps maintain signal quality in environments with potential sources of interference.

- Compliance with Standards: Cables that meet or exceed industry standards for signal integrity, impedance, and other electrical characteristics are likely to perform well in TDR testing. Compliance with standards ensures interoperability and compatibility with a wide range of devices.

- Quality of Materials: The choice of materials used in the cable’s construction, including conductors and insulation, can impact its electrical performance. High-quality materials contribute to lower signal loss and better overall performance.

- Precision in Manufacturing: Cables manufactured with high precision and quality control measures are more likely to exhibit consistent electrical characteristics. Precise manufacturing processes contribute to uniformity in cable performance.

- Design Considerations: The overall design of the cable, including its construction and layout, can influence its electrical properties. Cables designed with a focus on signal integrity and reliability are more likely to perform well in TDR testing.

Cables that pass TDR testing with ultra excellent performance are well-suited for applications requiring high-speed and reliable data transmission, such as in data centers, telecommunications, and other demanding environments.

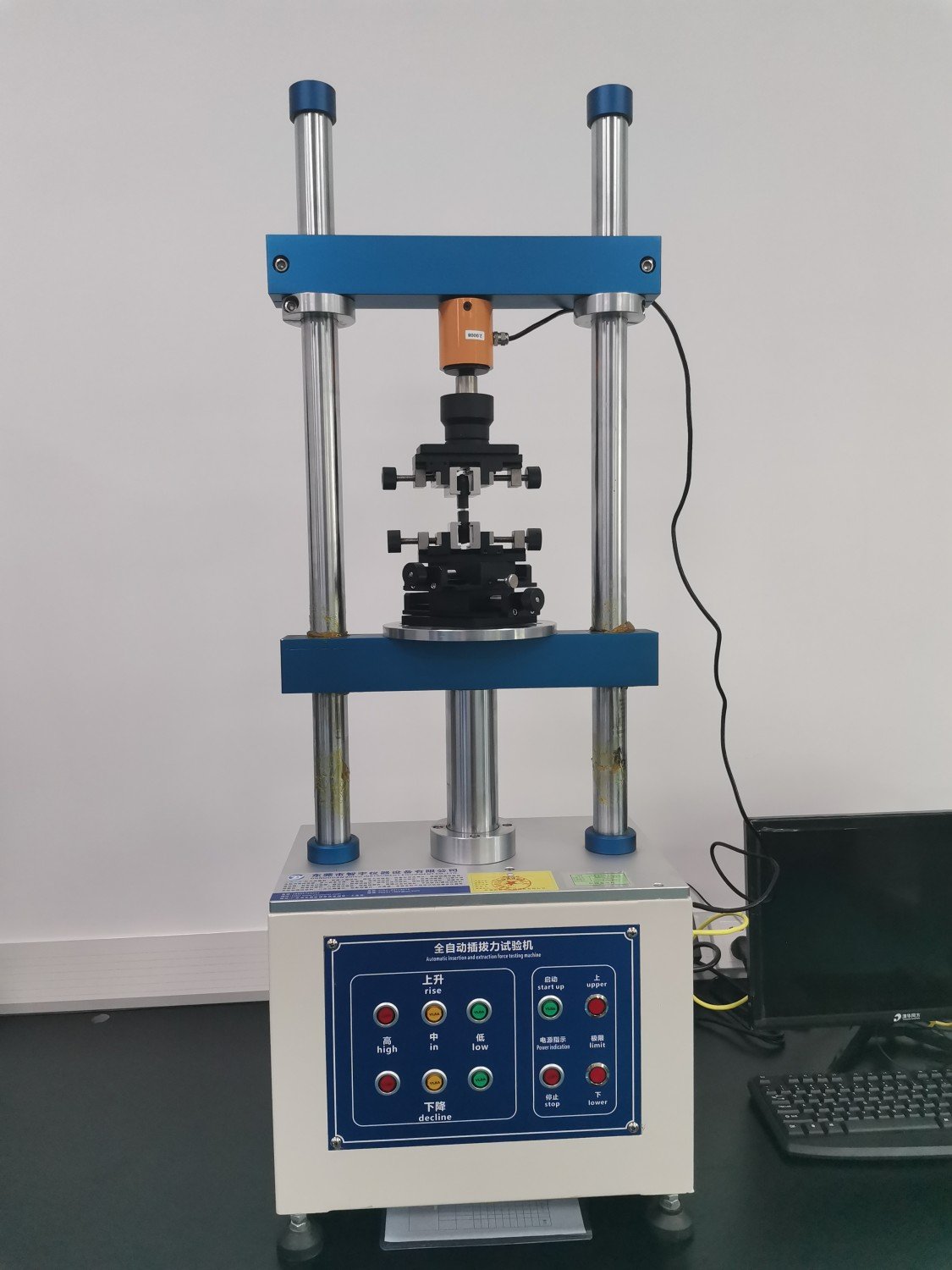

WE STAR FIRE, as a professional Audio Video connectivity solution as well as optical fiber communication manufacturing vendor and provider since 2006, We are ISO/BSCI certified factory, HDMI Adopter, DP VESA member, USB-IF member, the quality control system covering IQC/ IPQC/ OQC/ QA, before sending the samples to clients, We always do various reliability testing to ensure our products with good performance from each aspect.

If you would like to find a long-term reliable A/V connectivity solution partner, Pls. kindly connect us at sales@starfiretechcn.com