Table Of Content

Table Of Content

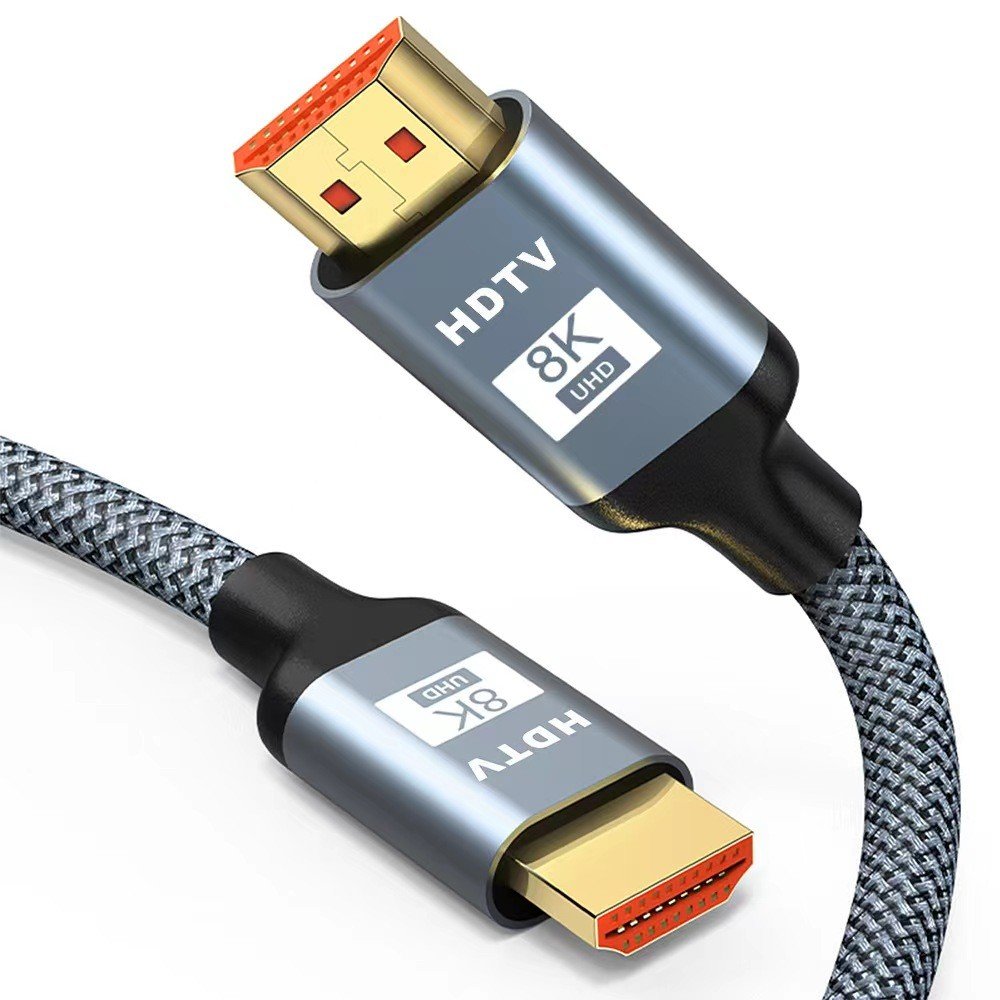

Reliability testing of premium cables is crucial for several reasons, especially when dealing with high-quality or premium-grade cables designed for critical applications. Here are some key reasons why reliability testing is essential for premium cables:

- Quality Assurance:Reliability testing ensures that premium cables meet or exceed the specified quality standards. This helps in maintaining consistency and reliability across batches or production runs.

- Performance Verification:Premium cables are often designed for high-performance applications where the stakes are high. Reliability testing helps verify that the cables can consistently deliver the specified levels of performance under various conditions.

- Durability Assessment:Premium cables are expected to withstand rigorous conditions and offer extended operational lifetimes. Reliability testing simulates various environmental factors, mechanical stress, and other stressors to assess the durability of the cables over time.

- Risk Mitigation:Testing helps identify and mitigate potential risks associated with cable failure. This is particularly important in critical applications such as data centers, aerospace, medical equipment, and industrial automation, where cable failure could have serious consequences.

- Compliance with Standards:Premium cables often need to meet stringent industry standards. Reliability testing ensures that the cables comply with these standards, providing confidence to end-users that they are purchasing a product that adheres to recognized quality benchmarks.

- Customer Satisfaction:Premium cables are typically associated with higher customer expectations. Reliability testing helps ensure that the cables not only meet but exceed customer expectations, leading to increased customer satisfaction and loyalty.

- Preventing Downtime:In applications where downtime is costly or unacceptable, such as in data centers or industrial automation, the reliability of cables is critical. Rigorous testing helps identify potential issues before deployment, reducing the risk of unexpected failures and minimizing downtime.

- Long-Term Performance:Premium cables are often used in installations where they are expected to perform reliably for an extended period. Reliability testing assesses the long-term performance and stability of the cables, considering factors like signal integrity, insulation resistance, and overall reliability over time.

- Consistency in Production:Reliability testing ensures that each cable produced consistently meets the specified performance criteria. This is essential for maintaining the reputation of premium cable manufacturers and instilling confidence in customers.

- Market Competitiveness:A commitment to reliability through testing can enhance the competitiveness of premium cables in the market. Products that have a reputation for reliability are more likely to be preferred by customers, contributing to market success.

In summary, reliability testing is a proactive measure that helps ensure premium cables perform as expected, are durable, and meet or exceed industry standards. This testing is essential for maintaining quality, preventing issues in the field, and instilling confidence in customers who rely on premium cables for critical applications.

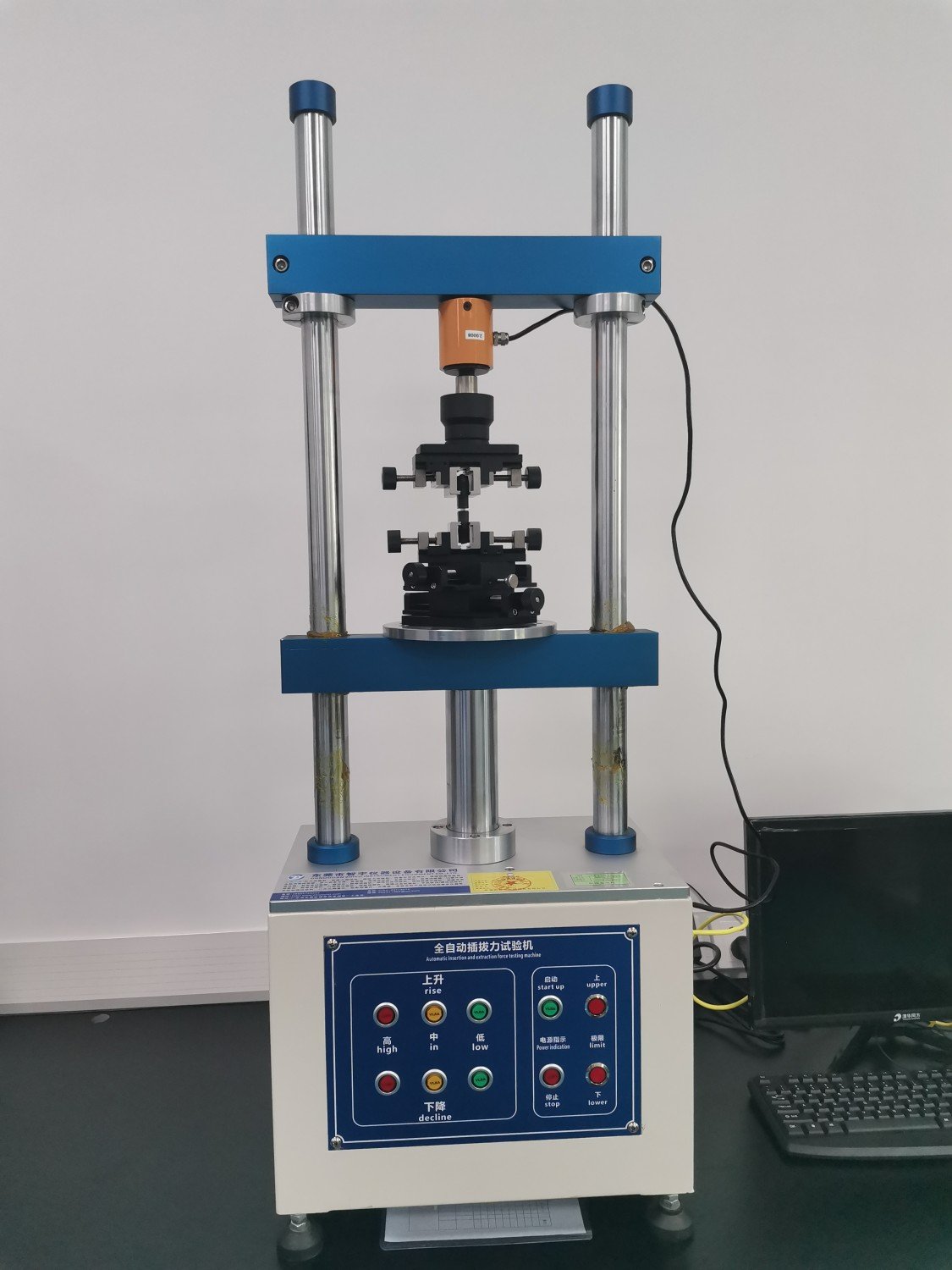

Our STAR FIRE cables before mass production, a series of reliability tests: such as: connector salt spray test, plug and pull test, swing test, impedance test, high and low temperature test, TDR testing etc., to ensure that our products have excellent performance, rather than a simple functional test OK, we regard quality as the life of the enterprise!

If you would like to find a long-term reliable A/V connectivity solution partner, Pls. feel free to contact us. Email: sales@starfiretechcn.com