Table Of Content

Table Of Content

On This Saturday morning, I picked up an Australian customer at the ShenZhen Shangri-La Hotel, Since it took 2 hours to get from the hotel to the company, we talked a lot along the way. I have the following deep feelings and would like to share with you:

1. Since we have communicated for 3 years by Email, Message, Cellphone, it is the first time to meet face by face, and the client came to visit the company on Saturday, and some Chinese suppliers cannot be scheduled. I am very grateful that this customer is willing to share his weekend time to visit, so I brought Chinese good BLACK TEA as a gift to the customer. When the customer received the gift, he took it with both hands and bowed to thank.

The more outstanding a person is, the more humble and polite he is, the more grateful he is! A person’s character and quality are reflected in the details.

2. This client was born in Sri Lanka. After graduating from university, he did not give up on continuing to improve himself. After finishing MBA, he chose to work in Australia. In just 4 years, he grew into a product director of a well-known brand in Australia. The better The harder you work, the better you are;

3. During the entire business trip, due to jet lag and business visits as well as need confirm and reply to various emails, so the sleep time per day is only about 4-5 hours, but when I see the guest and the whole communication process, I feel He is very energetic, and does not feel tired at all;

4. Listen to the sharing, their CEO has a good management style, fully believes and respects every talent, and gives everyone enough trust and freedom. Every week, they only need to work in the company on Tuesday, Wednesday, and Thursday. Other times, You can WORKING FROM HOME, WORKING FROM ANYWHERE, the team members are like brothers and sisters, there is no internal friction, they always support and help each other, and the CEO is like everyone’s friend, friendly, charismatic, and can fully mobilize Everyone’s subjective initiative and enthusiasm, everyone can work hard automatically and consciously. In such a difficult environment in the past 3 years, their company can continue to grow every year, and they have acquired 3 companies in the past 3 years;

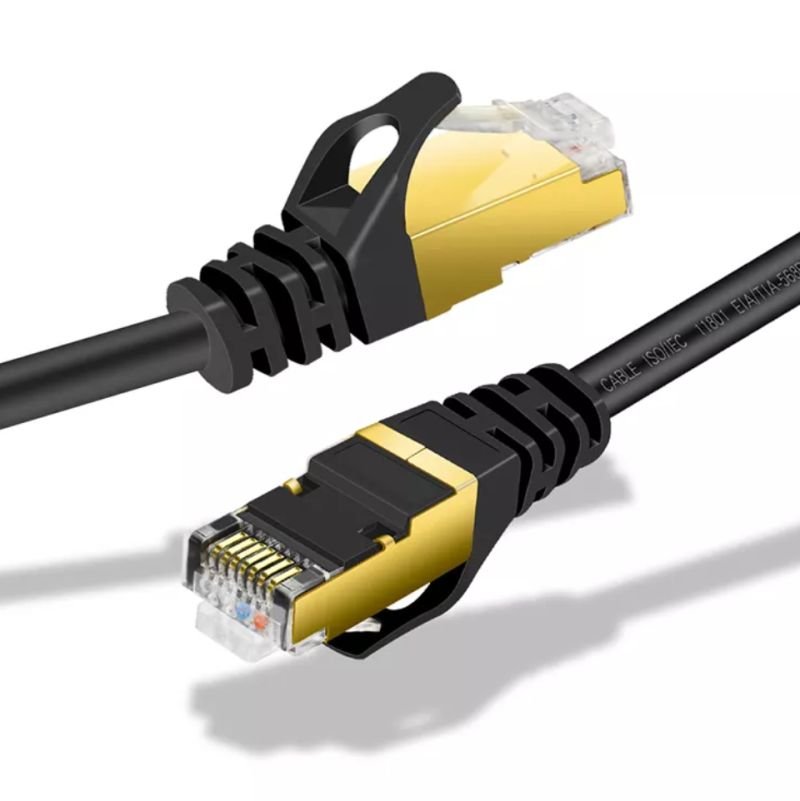

In the past 3 years, although there have been many communications, but because of COVID-19, This client is no way to visit our factory. After actually inspecting the factory on Saturday, they really understand why we are a trustworthy hashtag#connectivity solution hashtag#cable assy. supplier, mainly because of the following points:

1. We are an hashtag#ISO/ hashtag#BSCI certified company. Raw materials, WIP, and FG have passed the strict quality control process of hashtag#IQC/IPQC/OQC/QA. We will do our best to avoid any return rate and customer complaint;

2. The company is a member of hashtag#HDMI Adopter and hashtag#DP Association Member, and has obtained hashtag#USB 4 certification, hashtag#DP 2.1 40G certification, and multiple lengths of hashtag#HDMI 2.1/ hashtag#HDMI 2.0 have been certified by the HDMI association, We can meet the request that customer would like to launch full range with high end quality with certification

3. All cable raw materials are hashtag#UL-certified materials, standard fire protection grade, all raw materials are hashtag#ROHS, REACH, CP65 compliance, to avoid environmental risks;

4. Before all products are sent to customers for approval, in addition to the standard test of product performance, a series of hashtag#reliability test reports will also be provided, such as: connector hashtag#salt spray test, hashtag#insertion and removal force test, hashtag#wire high and low temperature test, hashtag#resistance Bending test, hashtag#swing test, hashtag#impedance test,

5. In addition to the above tests, there are also TDR characteristic test reports that general cable manufacturers cannot provide, such as signal loss, delay, attenuation testing, etc.;

6. In order to further ensure the stability of product performance, we pay attention to the standard twist length during raw cable production,

7. In order to ensure better conduction performance of the product, we hardly use CCS conductors to produce cables, and normally use high-quality OFC OR TC, BC, etc. (unless customers specifically request);

8. In order to ensure the stability of the production process, a fully automatic soldering machine is used for soldering. The tin spots are more plump and uniform, and it is not easy to causing any soldering problem then occur any electronic function problem during transportation. At the same time, a laser machine is used to complete the core wire peeling to avoid manual work.

9. For a better EMI effect of the cable, we use tinplate + industry A-grade copper foil process;

10. In order to make the wire stronger and more durable, the internal structure is made of aluminum foil, mylar, and 168 weaving;

11. In order to prevent oxidation of the connector, we use 24K gold plating instead of 18K;

12. In order to further make the product have a long life time, we adopt the in-mold injection molding process, and never use the dispensing assembly process;

The Details determine success or failure, quality is the life of an enterprise!

I fully understand that customers dare not switch vendors easily before they come to the factory. After all, the original supplier has also cooperated for many years. New things have opportunities and risks!

The customer said: He has to witness it with his own eyes, and he will be at ease when he comes to confirm it in person. This visit, he is very satisfied with everything he witnessed in person!

Looking forward the cooperation can be moved to the next step.

To Life, Keep Moving Always…